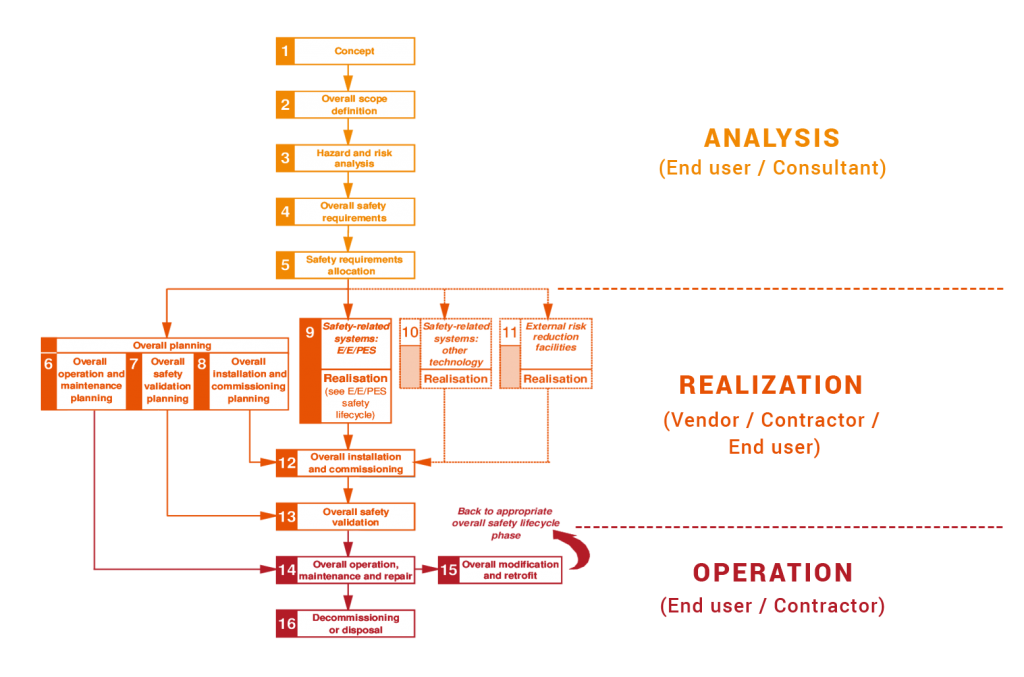

We provide a comprehensive approach to ensure compliance with all requirements of a Safety System as per its Life Cycle according to IEC 61511 and 61508.

This includes conceptual and detailed design of each SIF and any other instrumental (BPCS) or procedural / operational protection system needed to achieve appropriate level of risk as well as operational and maintenance planning to ensure integrity and reliability required throughout the operational life of the installation.